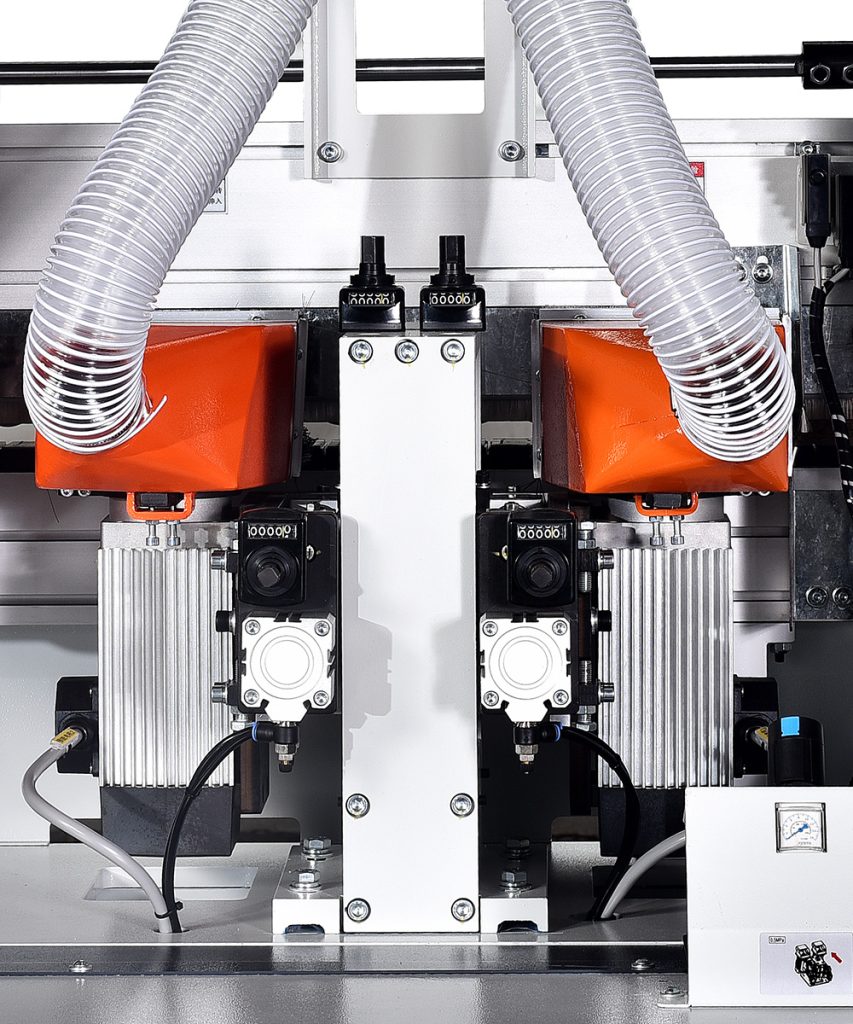

PRE-MILLING UNIT

Adopting dual 2.2kW high-frequency motors.

Mill the adhesive surface of the work piece.

Effectively eliminate edge collapse,

reduce adhesive lines, and achieve

more beautiful edge sealing .

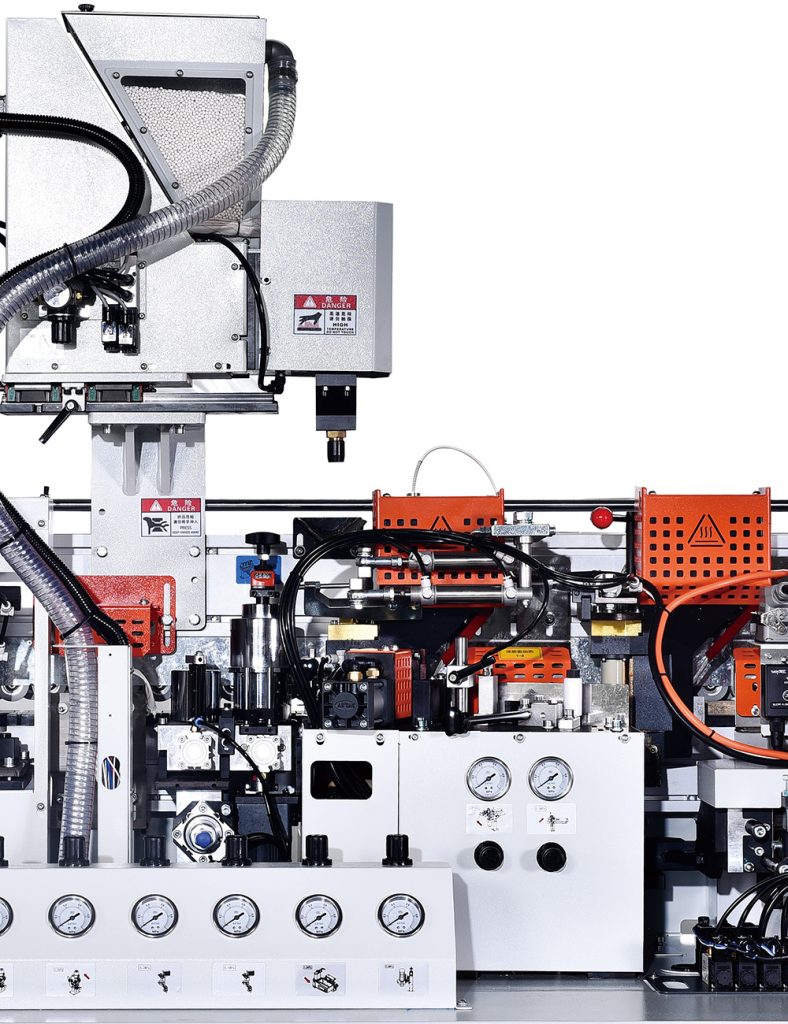

TAPE and GLUING & PASTING

1. To apply glue on the edge banding tape.The glue |

||||

pot is an upper mounted glue pot device that |

||||

automatically sucks glue to the quick pre dissolving box |

||||

and then injects glue into the glue pot through |

||||

the pre dissolving box. The advantage of the upper |

||||

mounted glue pot is that the glue will not carbonize |

||||

and the glue line will be smaller. |

||||

2. This structural design is a patented technology applied |

||||

by our company, which can prevent the edge banding |

||||

from easily deviating and curling. |

||||

3. This gluing method is to use adhesive on the styling |

||||

part and adhesive on the straight edge of the board. |

||||

the adhesion more firm and the edge sealing more stable. |

||||

Oblique edge pressing and pasting

Oblique edge pressing device: The straight edge and |

|||||||||||

oblique edge parts are alternately pressed and |

|||||||||||

formed to make the adhesion more firm. |

END CUTTING

There are a total of 2 motors for aligning, divided into |

||||||||||

front aligning and rear aligning, used to align the |

||||||||||

edge sealing end face. This institution uses special saw |

||||||||||

blades to make the cutting surface smoother. |

ÖNE ÇIKANLAR

BAŞLIK

AÇIKLAMA

ÖNE ÇIKANLAR

BAŞLIK

AÇIKLAMA

ÖNE ÇIKANLAR

BAŞLIK

Reviews

There are no reviews yet.