TECHNICAL PARAMETERS

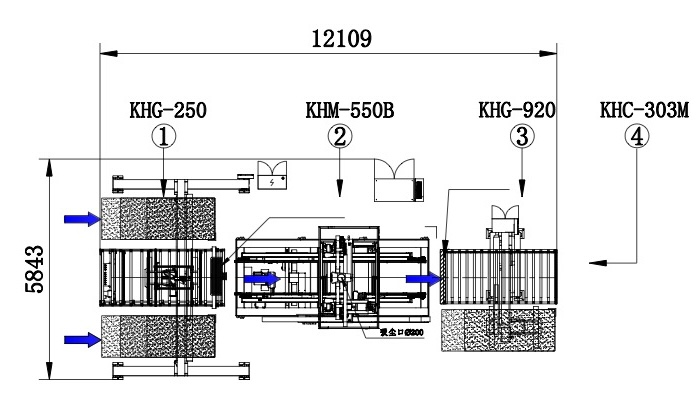

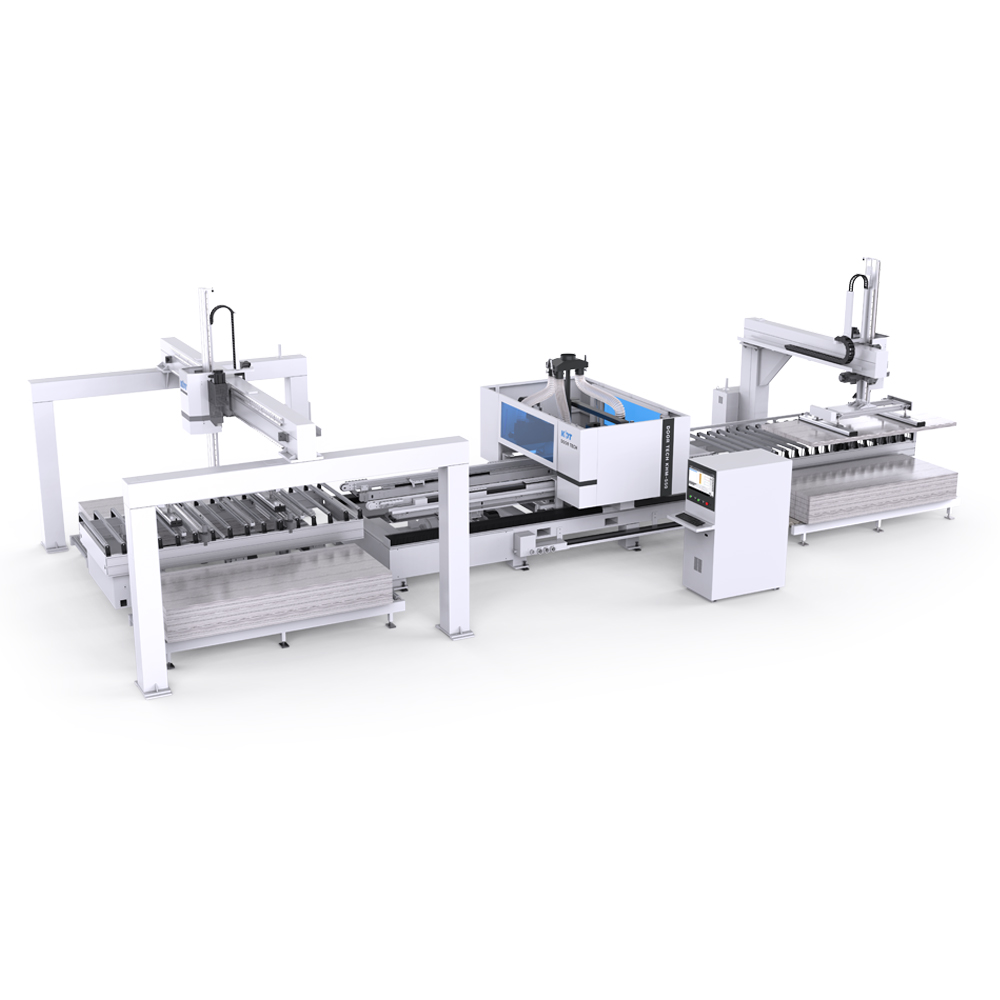

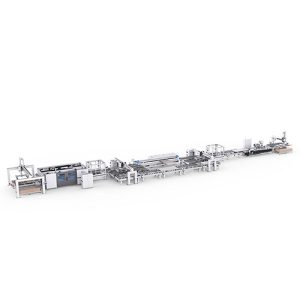

KHM-550B+KHG-250+KHG-920

| 1.Max. working size (mm) | 2500*1100mm(Width for surplus material ≤30mm) |

| 2.Min. working size(mm) | 1800*400mm(Width for surplus material≤30mm) |

| 3.Working thickness | 30-60mm |

| 4.Main saw parameter | 4*7.5kW(Φ300* Φ50) |

| 5.Scoring saw parameter | 4*1.5kW(Φ120* Φ30) |

| 6.Max.moving speed | 40m/min |

| 7.Vacuum sucker position | Servo positioning |

| 8.Workpiece position | Centering |

| 9.Working table height from ground | 960mm |

| 10.QTY of Dust outlet | Φ140*5 |

| 11.Total power | 53.2kW |

Ürün Videosu

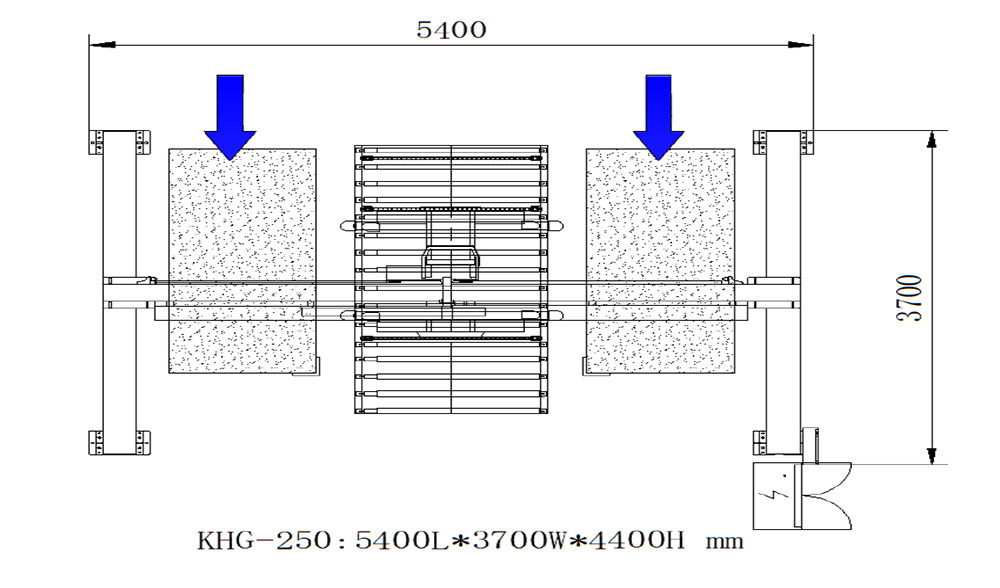

KHG-250 GANTRY LOADER

Three-station gantry loading machine, the whole machine is controlled by touch screen + PLC, can be connected (access to the central control system), and can be used independently as a stand-alone machine. The whole machine adopts a heavy-duty gantry structure; automatic infeeding in 4 directions ,can meet the infeeding needs of all customers. The movement uses high-power servo + planetary reducer, and the Z-axis uses high-strength special aluminum material to effectively ensure the stability of high-travel movements. Panel adsorption uses a whole-strip vacuum suction cup, which has stable suction force and a large adsorption area. Equipped with an automatic centering conveyor platform, which can automatically realize the centering positioning operation of panels.

Technical parameter

| Max processing size | 2500*1100mm |

| Panel length | 1800-2500mm |

| Panel width | 400-1100mm |

| Panel thickness | 30-60mm |

| Stacking height | 1300mm |

| Load-bearing | 100kg |

| Power | 3.25kW |

| Gross weight | 2500kg |

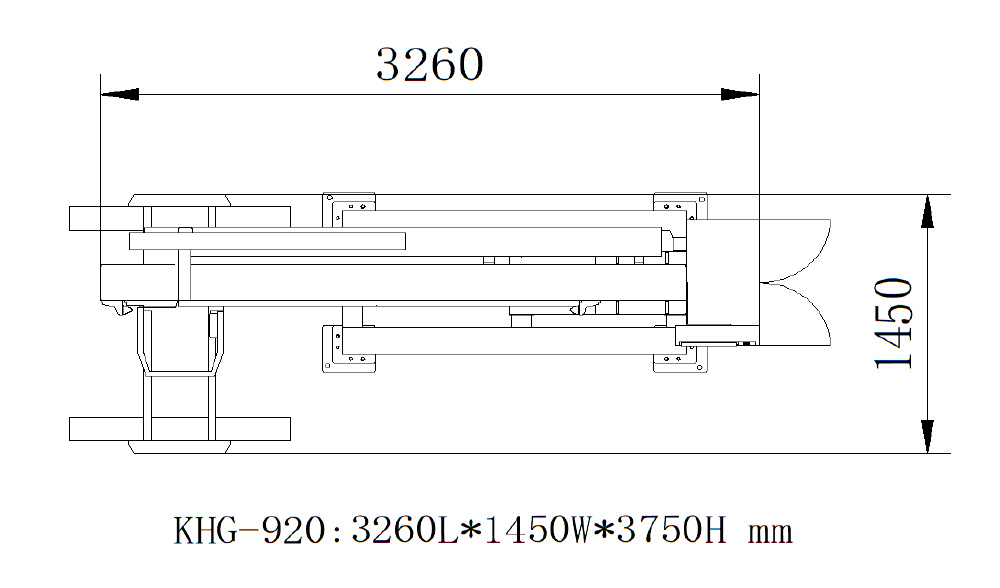

KHG-920 GANTRY UNLOADING

Single cantilever type loading machine, adopts touch screen and PLC. It can make production line ( connected with central control system). Can also be used as single machine. Machine adopts the European single cantilever unit and there is no other structural interference at the feeding side. It is flexible to use and occupies a small floor space which can also meet the requirement of the whole line feeding. The movement uses high-power servo and planetary reducer. Z-axis adopts high-strength special aluminum material and effectively ensure the stability of high-travel movements. Panel adsorption uses a whole piece of vacuum cup, which is stable with large adsorption area. The conveyor table can be optioned according to actual requirement.

Technical parameter

| Max.working size | 2500*1100mm |

| Panel length | 1800-2500mm |

| Panel width | 400-1100mm |

| Panel Thickness | 30-60mm |

| Stacking height | 1100mm |

| Bearing capacity | 100kg |

| Total power | 3.25kW |

| Overall size | 3260L*1450W*3750H mm |

Reviews

There are no reviews yet.