KD-610R

Ürün Açıklaması

Teknik Parametreler Ürün Videosu

Six sides NC drilling center, one operator with small workload. can be directly connected with a variety of splitting software. It is mainly used for various of artificial boards six sides drilling (through holes, semi-through holes, horizontal drilling) and also can proceed hogging and milling with small spindles. |

|

| 1.Six-sides drilling. Feed-in & Out-Feed at front. Small footprints occupied. Easy and quick install. 4 sets can be loaded in a 40 feet container. | |

| 2.Adopt dismountable extend support table at front and back, occupies a small area. | |

| 3.Software can simulate processing path, predict the processing time | |

| 4.Standard with panel thickness detection function. | |

KD-612KH

Ürün Açıklaması

1 üst – 1 alt motor grubu mevcuttur.

Tutucu açılımı: 60 mm

Eksen işlem hızı 140 m/dk’dır.

Boşaltma konveyörü mevcuttur.

Altta ve üstte freze motoru mevcuttur. Kanal testeresi mevcuttur.

İşlem parçası boyu ölçen lazer okuyucu bulunmaktadır.

Merkezi otomatik yağlama mevcuttur.

Teknik Parametreler Ürün Videosu

KD-612KS

Ürün Açıklaması

Teknik Parametreler Ürün Videosu

Double-drill package six sides NC drilling center has double-drill packages for simultaneous processing and more efficiency. Single-handed operation, small workload, can be directly connected with a variety of split software. It is mainly used for six faces (hinge holes, through holes, semi-through holes) of various kinds of artificial boards, horizontal drilling, and can simultaneously process symmetrical hole positions, also can do hogging and milling with small spindles. |

|

| 1.64mm min drilling distance between 2 drill bit package during simultaneous processing | |

| 2.With double gripper and long guide rail,gripper max speed up to 140m/min,auto detect hole position to avoid gripper exchange time. Gripper trip up to 5.5 meter,big board can working by one time catch,reduce processing time. | |

| 3.Adopt double translation air flotation table,move flexibly according to the hole position to improve the drilling accuracy and avoid fouling at the bottom. | |

| 4.Adopt double positioning mode,more accurate and efficient positioning of different panels. | |

| 5.Adopt belt conveyer dust collection,centralized remove all dust which fall into machine. | |

| 6.Software can simulate processing path,predict the processing time; | |

| 7.Processing record statistics,view production progress in real time. | |

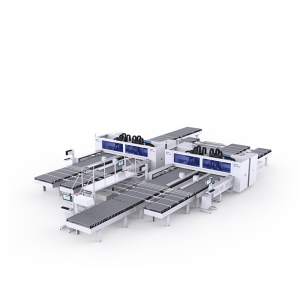

KD-612KSZ

Ürün Açıklaması

Teknik Parametreler Ürün Videosu

Double-drill package ,six sides NC drilling center has double-drill packages and 5 types ATC for simultaneous processing and more efficiency. Single-handed operation, small workload, can be directly connected with a variety of split software. It is mainly used for six faces (hinge holes, through holes, semi-through holes) of various kinds of artificial boards, horizontal drilling, simultaneously process symmetrical hole positions, also can do hogging and milling with small spindles. |

|

| 1.5 types ATC for spindle, easier to handle hogging, milling, lamella and other crafts; | |

| 2.With double gripper and long guide rail,gripper max speed up to 140m/min,auto detect hole position to avoid gripper exchange time. Gripper trip up to 5.5 meter,catch big board by one time ,reduce processing time. | |

| 3.Adopt double translation air flotation table,move flexibly according to the hole position to improve drilling accuracy and avoid fouling at the bottom. | |

| 4.Adopt double positioning modes,more accurate and efficient positioning of different panels. | |

| 5.Adopt belt conveyer dust collection,centralized remove all dust which fall into machine. | |

| 6.Software can simulate processing path,predict the processing time; | |

| 7.Record processing statistics,view production progress in real time. | |

KD-612G

Ürün Açıklaması

2 üst – 1 alt motor grubu mevcuttur.

Tutucu açılımı: 60 mm

Eksen işlem hızı 140 m/dk’dır.

Boşaltma konveyörü mevcuttur.

Altta ve üstte freze motoru mevcuttur.

İşlem parçası boyu ölçen lazer okuyucu bulunmaktadır.

Merkezi otomatik yağlama mevcuttur.

Teknik Parametreler Ürün Videosu

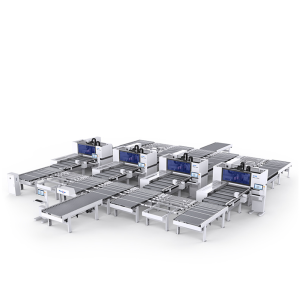

KD-812A

Ürün Açıklaması

Teknik Parametreler Ürün Videosu

Double Work-station Throughfeed Six-side Drilling Machine;6 groups drill package working together, more efficient. Match with various design and nesting software. Mainly use for variety manmade panel with big capacity drilling, can processing 2 panels at same time. |

|

| 1.Double worksstaion and six-side throughfeed drilling machine, with total 106 drill bits(82V+24H), intelligent and efficient; | |

| 2.Dual workstation independent operation, processing different process boards simultaneously, with drilling efficiency of 8 pieces per minute. | |

| 3.Equipped with main and auxiliary automatic feeding and discharging table devices, which can be connected to single or multiple machines, and equipped with automatic positioning device for shifting materials without manual operation. | |

| 4.Equipped with an automatic scanning gun as standard, scanning workpiece labels to achieve hole position processing. | |

| 5.Independently developed control system, visualizing the optimal machining path. | |

| 6.The sub station is equipped with photoelectric board width detection and intelligent calibration of the sub station positioning reference, ensuring high processing accuracy. | |

KDT-6052K

Ürün Açıklaması

Teknik Parametreler Ürün Videosu

KDT-6052K |

|

Features: high quality CNC multi-row drilling machine, mobile drilling machine and positioning mechanism driven by high precision servo drive, reduce the number of turning plate and adjust machine time, greatly improve drilling efficiency. Includes automatic feeding device, which can enter and leave the board quickly and automatically. |

|

| 1.1. Standard PC is available for remote operation.2. CNC multi-row drilling can shorten the time of machine adjustment and improve the precision of machine adjustment, and the processing data can be stored in the system and called at any time.3. The mobile drill row and positioning mechanism are driven by high-precision servo, and the input data of the screen of the industrial control unit are automatically positioned to the designated position.4. The equipment includes 0-5 groups of vertical drilling row on top, 0-8 groups of vertical drilling row on bottom, 0-2 groups of horizontal drilling row on bottom, and drill row free combination operation;5. Automatic drilling software, which is suitable for drilling holes in all directions in one working procedure of panel furniture production, with high efficiency and high precision;6 drill, vertical drilling group adopts pneumatic locking system, for each group of boring row of independent 0-90 ° Angle adjustment;7. Adopt Taiwan PMI linear guide rail, with high precision, good rigidity and more accurate drilling. | |

KDT-6052

Ürün Açıklaması

Manuel ayarlı endüstriyel

Hat delik makinesi

5 alt, 2 yatay olmak üzere toplam 7 kafadır.

Teknik Parametreler Ürün Videosu

KDT-6032TS

Ürün Açıklaması

Endüstriyel çekmece delik makinesi

Şarjörlü

Otomatik boşaltmalı(servolu asansörlü)

6032 modelinde Alt:3 Yan:2 delik grubu

6022 modelinde Alt:2 Yan:2 delik grubu

Teknik Parametreler Ürün Videosu

KDT-533

Ürün Açıklaması

3 kafa delik makinesidir. Magazinler 90 derece döndürülebilir

Teknik Parametreler Ürün Videosu

KDT-6462K

Ürün Açıklaması

KDT-6052K

Features: high quality CNC multi-row drilling machine, mobile drilling machine and positioning mechanism driven by high precision servo drive, reduce the number of turning plate and adjust machine time, greatly improve drilling efficiency. Includes automatic feeding device, which can enter and leave the board quickly and automatically.

1.1. Standard PC is available for remote operation.2. CNC multi-row drilling can shorten the time of machine adjustment and improve the precision of machine adjustment, and the processing data can be stored in the system and called at any time.3. The mobile drill row and positioning mechanism are driven by high-precision servo, and the input data of the screen of the industrial control unit are automatically positioned to the designated position.4. The equipment includes 0-5 groups of vertical drilling row on top, 0-8 groups of vertical drilling row on bottom, 0-2 groups of horizontal drilling row on bottom, and drill row free combination operation;5. Automatic drilling software, which is suitable for drilling holes in all directions in one working procedure of panel furniture production, with high efficiency and high precision;6 drill, vertical drilling group adopts pneumatic locking system, for each group of boring row of independent 0-90 ° Angle adjustment;7. Adopt Taiwan PMI linear guide rail, with high precision, good rigidity and more accurate drilling. Teknik Parametreler Ürün VideosuKDT-6052K

Ürün Açıklaması

Teknik Parametreler Ürün Videosu

KDT-6052K |

|

Features: high quality CNC multi-row drilling machine, mobile drilling machine and positioning mechanism driven by high precision servo drive, reduce the number of turning plate and adjust machine time, greatly improve drilling efficiency. Includes automatic feeding device, which can enter and leave the board quickly and automatically. |

|

| 1.1. Standard PC is available for remote operation.2. CNC multi-row drilling can shorten the time of machine adjustment and improve the precision of machine adjustment, and the processing data can be stored in the system and called at any time.3. The mobile drill row and positioning mechanism are driven by high-precision servo, and the input data of the screen of the industrial control unit are automatically positioned to the designated position.4. The equipment includes 0-5 groups of vertical drilling row on top, 0-8 groups of vertical drilling row on bottom, 0-2 groups of horizontal drilling row on bottom, and drill row free combination operation;5. Automatic drilling software, which is suitable for drilling holes in all directions in one working procedure of panel furniture production, with high efficiency and high precision;6 drill, vertical drilling group adopts pneumatic locking system, for each group of boring row of independent 0-90 ° Angle adjustment;7. Adopt Taiwan PMI linear guide rail, with high precision, good rigidity and more accurate drilling. | |

KDT-6052

Ürün Açıklaması

Manuel ayarlı endüstriyel

Hat delik makinesi

5 alt, 2 yatay olmak üzere toplam 7 kafadır.

Teknik Parametreler Ürün Videosu

KDT-6032TS

Ürün Açıklaması

Endüstriyel çekmece delik makinesi

Şarjörlü

Otomatik boşaltmalı(servolu asansörlü)

6032 modelinde Alt:3 Yan:2 delik grubu

6022 modelinde Alt:2 Yan:2 delik grubu

Teknik Parametreler Ürün Videosu

KN-3710DE

Ürün Açıklaması

Endstüstriyel Düzlem CNC

Süpürme ünitesi standart

Sonradan hat haline dönüştürülebilinir.

Çalışma alanı: 3100*2150

Bıçak magazin sayısı: 12 adet

Vakum pompa sayısı: 2 adet

Bıçak okuma sensörü

Delik grubu mevcuttur.

Merkezi otomatik yağlama mevcuttur.

Teknik Parametreler Ürün Videosu

KN-3713DE

Ürün Açıklaması

Endstüstriyel Düzlem CNC

Süpürme ünitesi standart

Sonradan hat haline dönüştürülebilinir.

Çalışma alanı: 4200*2150

Bıçak magazin sayısı: 12 adet

Vakum pompa sayısı: 2 adet

Bıçak okuma sensörü

Delik grubu mevcuttur.

Merkezi otomatik yağlama mevcuttur.

Teknik Parametreler Ürün Videosu